Why fire to a ‘Cone’ instead of a specified temperature? Pyrometric Cones and Kilns Explained

Why fire to a ‘Cone’ instead of a specified temperature? Pyrometric Cones and Kilns Explained

When firing ceramic ware it is generally required to fire to a specified 'Cone' instead of a temperature. But ‘why?’ you may ask. And what is a ‘Cone’ anyway?

Pyrometric cones are a diagnostic tool used to measure a reaction achieved at a specific time and temperature during the firing process. At a certain point during a firing they will deform, and this action can enable the kiln to shut off automatically at the proper point (as in the case of the mini bar and Kiln Sitter) or simply to record what happened during the firing.

The exact moment a cone deforms depends primarily upon a combination of time and temperature and the temperature at the time ‘Cone’ is achieved depends upon the speed at which a temperature is achieved (also known as a rate of fire).

With this concept in mind, it is easier to understand why we use ‘Cones’ as unit of measurement for firing and do not use temperature alone.

If you are looking for a ceramic kiln, Ceramicraft offers a large selection of single and three phase Cress and Paragon kilns to suit individuals and studios of all sizes and budgets.

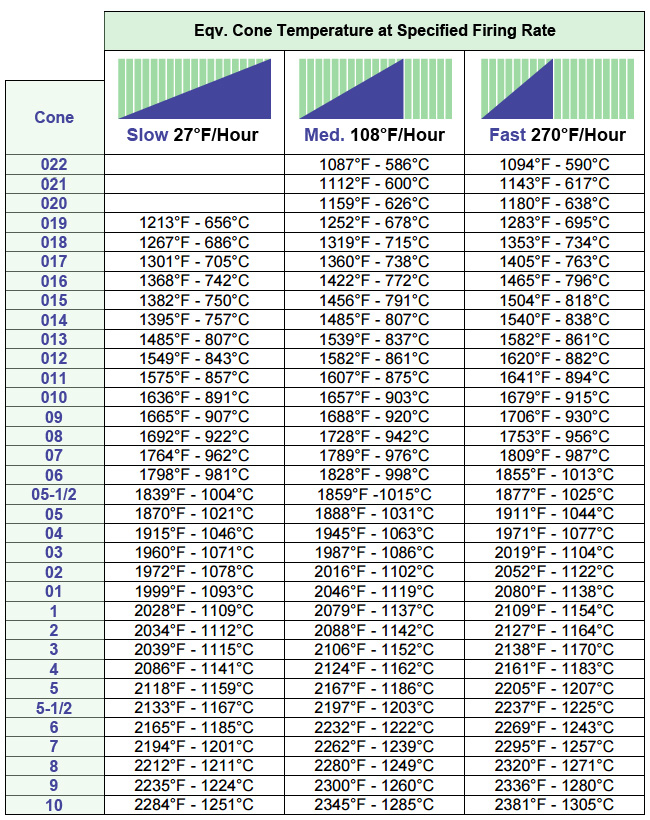

Pyrometric Cone Firing Chart

Please note that Pyrometric Cone Firing Chart provided below gives 3 different temperatures for each cone number. As discussed above, the equivalent cone temperature depends upon the speed/firing rate at which a temperature is achieved.

Generally speaking, a medium firing rate is used for glaze firings for ceramics, porcelain and china wares. Higher firing rates are typically reserved for lower temperature firings for things such as decals and lustres. And Low firing rates are suitable for bisque.